Product Introduction

General

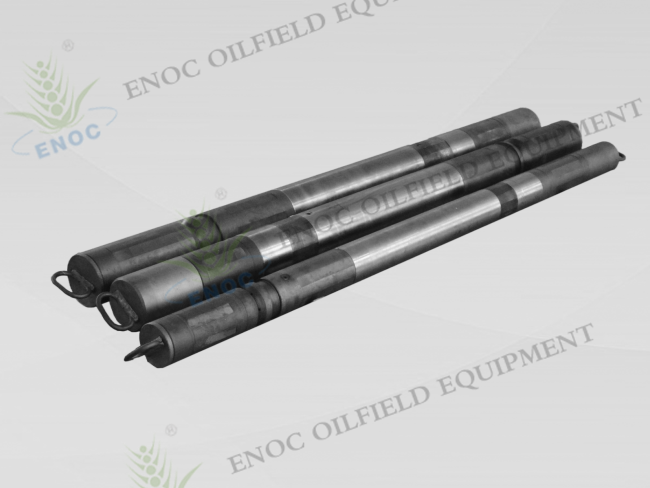

The RTTS packer is a full-opening, hookwall packer used for testing, treating, and squeeze cementing operations. In most cases, the tool runs with a circulating valve assembly.

The packer body includes a J-slot mechanism, mechanical slips, packer elements, and hydraulic slips. Large, heavy-duty slips in the hydraulic holddown mechanism help prevent the tool from being pumped up the hole. Drag springs operate the J-slot mechanism on ≤ 3 1/2-in. (88.9-mm) packer bodies, while larger packer sizes ≥ 4-in. (101.6 mm) use drag blocks. Automatic J-slot sleeves are standard equipment on all packer bodies.

The circulating valve, if used, is a locked-open/locked-closed type that serves as both a circulating valve and bypass. The valve automatically locks in the closed position when the packer sets. During testing or squeezing operations, the lock prevents the valve from being pumped open. A straight

J-slot in the locked-open position matches with a straight

J-slot (optional) in the packer body. This combination eliminates the need to turn the tubing to close the circulating valve or reset the packer after the tubing has been displaced with cement.

Features and Benefits

• The full-opening design of the packer mandrel bore allows large volumes of fluid to pump through the tool.

Tubing-type guns and other wireline tools can be run through the packer.

• The packer can be set and relocated as many times as necessary with simple tubing manipulation.

• Tungsten carbide slips provide greater holding ability and improved wear resistance in high-strength casing. Pressure through the tubing activates the slips in the hydraulic holddown mechanism.

• An optional integral circulating valve locks into open or closed position during squeezing or treating operations, and opens easily to allow circulation above the packer.