Product Introduction

General

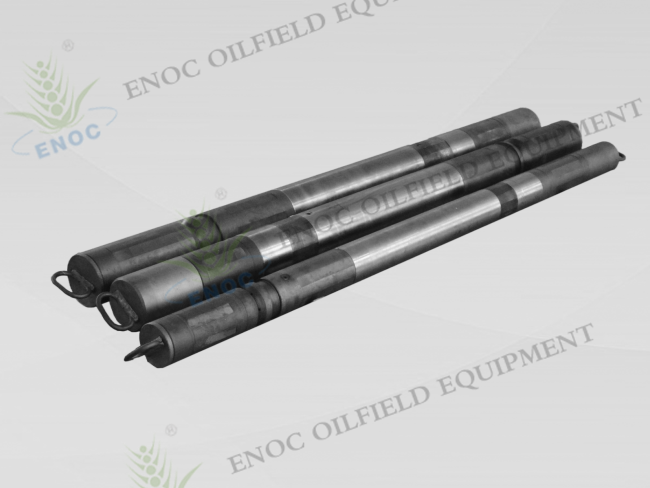

The Pressure Operated tester valve (LPR-N Valve) is a full- opening, annulus pressure-operated valve. It measures multiple closed-in pressures in cased holes where pipe manipulation is restricted and a full-opening string is required. The nitrogen chamber is charged at the surface to a selected pressure determined by surface temperature, bottomhole temperature, and bottomhole pressure. If the intended test requires a permanent packer that uses a stinger mandrel or seal nipple, a variety of ENOC bypass tools are available, depending on field application, to help ensure that the formations and downhole equipment are protected from excessive pressure buildup.

Features and Benefits

• The ball valve operates independently of internal pressure changes, such as with acidizing or fracturing operations.

• Advanced materials and processes provide a unique metal-to-metal seat for exceptional gas-holding capabilities.

• The Pressure Poerated tester valve has been through an extensive five-day qualification testing at 400°F and15,000 psi burst and collapse pressures.

• An open-in feature allows the operator to run the Pressure Poerated tester in the hole with the ball valve opened or closed.

• Fluids can be spotted or circulated through the PRESSURE POERATED tester with the packer unseated.

A double nitrogen chamber can be added to the Pressure Poerated tester for use in deep, hot, high-pressure wells to reduce the operating pressure.

Operation

The Pressure Poerated tester valve is composed of a ball valve section, a power section, and a metering section.

The ball valve section provides multiple downhole closures. It is turned by operating arms. The power section has a floating piston that is exposed to the hydrostatic pressure on one side and pressurized nitrogen on the other side. With the packer set, pump pressure applied to the annulus moves the piston downward, activates the operating arms, and opens the ball valve. When the annulus pressure is released, pressurized nitrogen returns the piston upward, closing the ball.

After the surface equipment is properly installed, the packer is set, and the rams are closed, pressure is applied to the annulus, using rig pumps to operate the Pressure Poerated tester.